Safety Features

| Sign In | Join Free | My esadidasol.com |

|

Brand Name : Precise Heater

Model Number : UH202

Certification : CSA,UL,CE

Place of Origin : China

MOQ : 1 unit

Price : US$3,000 - 9,000 / unit

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 30 units per month

Delivery Time : 15-25 days

Packaging Details : Export Wooden Case

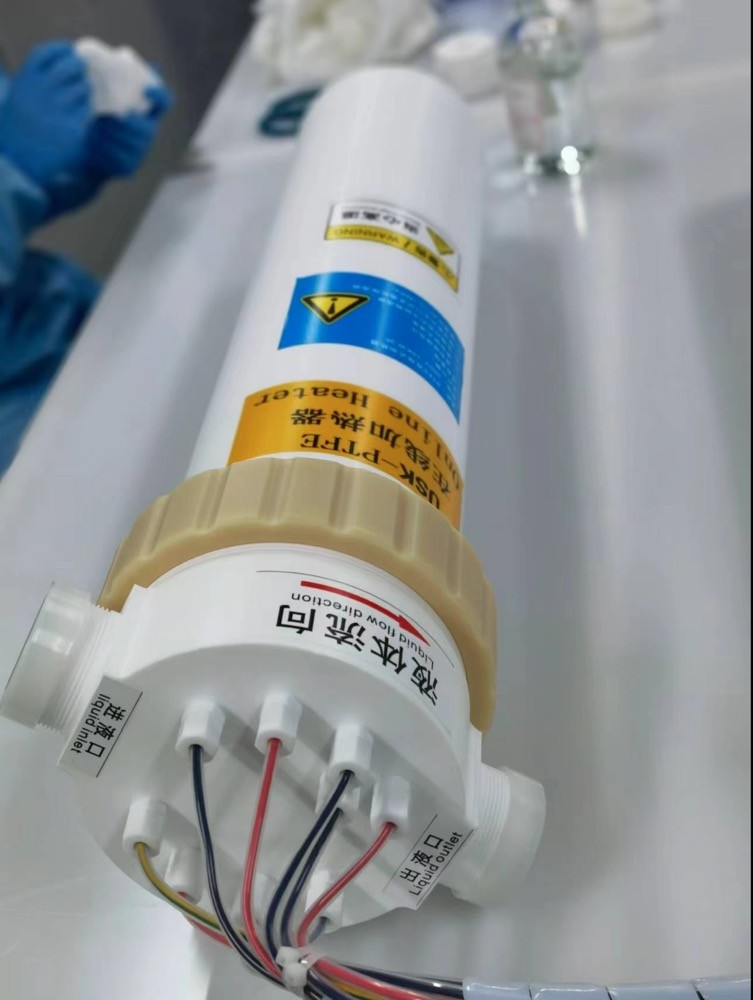

Material : PFA/PTFE/PVDF

Color : White

Safety Features : Liquid level sensor,Ground wire options

Applications : Semiconductor Wet Processes,Solar/Photovoltaic Wafer Cleaning

SPECIFICATIONS : 1,000 watts up to 18,000 watts

Voltages : 110 to 600 volts, single or three phase

Inline Chemical Heater Performs Unmatched Semiconductor Process Fluid Heating

Now heat semiconductor process fluids up to 210°C!

Faster heatup: Single heater chamber sizes up to 18kW.

Rapid installation: Customized plumbing connections

Long heater life for reduced cost of ownership (COO):

Patented heater gas purge system continuously removes any chemical permeation and ensures long element life.

Long heater life and clean operating: Patented heater gas purge system continuously removes chemical permeation and ensures exceptionally long element life. This system also protects against any potential ionic contamination of the chemistry.

Rugged construction: Thick walled chamber provides long service life in the harshest high temperature applications.

Exceptionally clean performance: Thick fluoropolymersheath minimizes permeation. Element purge monitoring minimizes ionic contamination potential. Cleanroom assembly and testing ensures the highest manufacturing standards.

Outstanding chemical compatibility: All fluoropolymerwetted parts compatible with virtually any chemistry.

Excellent temperature stability: Low watt density design enables accurate control of process temperature.

Applications Include:

SC1: ammonium hydroxide (NH4OH), and hydrogen peroxide (H2O2)

SC2: hydrochlorice acid (HCl) and hydrogen peroxide Buffered oxide etch (BOE) process: hydrofluoric acid (HF) and ammonim fluoride (NH4F)

Nitride etch/strip: phosphoric acid (H3PO4)Various acids such as:

Hydrochloric (HCl)

Hydrofluoric (HF)

Acetic (C2H4O2)

Nitric (HNO3)

Sulfuric (H2SO4)

Sulfuric acid and hydrogen peroxide

Sulfuric acid and ozone (O3)

Hydrofluoric acid and glycol (C2H6O2)

Potassium hydroxide (KOH)

Sodium hydroxide (NaOH)

Electroless nickel Electroless copper Electroless gold Deionized water

Some solvents (consult factory)

Benefits and Specifications

Unmatched heating of semiconductor process fluids upto 210°C.

Patented heater gas purge system ensures long element life and reduced cost of ownership.

Thick walled chamber provides long service life in the harshest high temperature applications.

Element purge monitoring minimizes ionic contamination potential. Cleanroom assembly and testing ensures the highest manufacturing standards.

All fluoropolymer wetted parts provide outstandingcompatibility with virtually any chemistry.

Low watt density design enables precise and stable control of process temperature.

PVDF high temperature mounting brackets (Hightemperature model)

Options:

Horizontally mounted configuration

Integral cooling coils

100 ohm RTDs or “J”, “K”, or “E” type process and

element thermocouples

Lower watt density heaters for special applications

Specifications:

Service:

• Inline chemical heater with all fluoropolymer wetted

surfaces for virtually any wet chemistry application.

Temperature Range: Up to 210°C.

Maximum Working Pressure:

• 100 PSIG (7 Bar) at 25oC

• 43 PSIG (. Bar) at 180oC

Heater Sizes: 1,000 watts up to 18,000 watts

Heater Voltages Available:

• 200 to 600 volts, single or three phase (12kW and

larger requires three phase).

Watt Density: 10 watts per square inch (1.5w/cm2)

Fluid Connections Available:

• 1⁄4” (6mm) to 1” (25mm) flared

• 1⁄2” (12mm) to 1” (25mm) Super 300 Type Pillar®•

Other connections available, consult factory

Third Party Certificatons: CE, UL, Semi S2 and S3

Element Purge:

• Small amount of clean dry air (CDA) or N2 gas flows

between the metal grounded element and the PTFE sheath

Applications

Semiconductor Wet Processes

Sterilization/Cleaning

Solar/Photovoltaic Wafer Cleaning

Liquid level sensor

Ground wire options

Over-temperature thermocouple

Process thermocouple

Options

Thermal cutoff

Thermocouples

Fiber-optic liquid level sensor

RTD sensors

Pressure relief valve

| Model | LP1 | LP7 |

| Wetted Material | PVDF/PFA | PVDF/PFA |

| Housing Material | Pipe | Pipe |

| Max Temp | 95°C | 95°C |

| Pressure | 60 psi at 95°C | 60 psi at 95°C |

| Power* | 1-15 kW | 1-18 kW |

| Accuracy | ± 0.1o C | ± 0.1o C |

| Voltages** | 200-480 VAC, 1 and 3-phase | 200-600 VAC, 1 and 3-phase |

| Flow | 0.5-32 gpm (1.9-122 L/min) | 0.5-32 gpm (1.9-122 L/min) |

| Benefits | Variable height | Higher flow, kW |

|

|

210C Inline Chemical Heater Unmatched Semiconductor Process Inline Fluid Heater Images |